So you want to get into electronics?

January 6, 2025

For whatever reason you decided that you would like to learn and "get good" at electronics. Congratulations, this is the right place! This article will document my journey and highlight things I wish I knew when starting out. Hopefully this resource will help you get started while avoiding some of the common pitfalls. There will be no direct links to the exact details you need to learn, this will rather be a general pointer in the right direction for you to do your own research and learn the all important skill of searching information along the way. I start throwing jargon pretty early on, so try and practice said searching skills if you get confused about anything at any point, also some parts are intended to be read later once you tipped your toes into the hobby (like the oscilloscope discussion).This article has been vetted and adjusted with the guidance of some of my friends who also do electronics as their "thing" too in order to ensure that nothing was left out or over/under represented. Despite this I urge you to read other resources out there because advice is not universal and the more sources you check, the better.

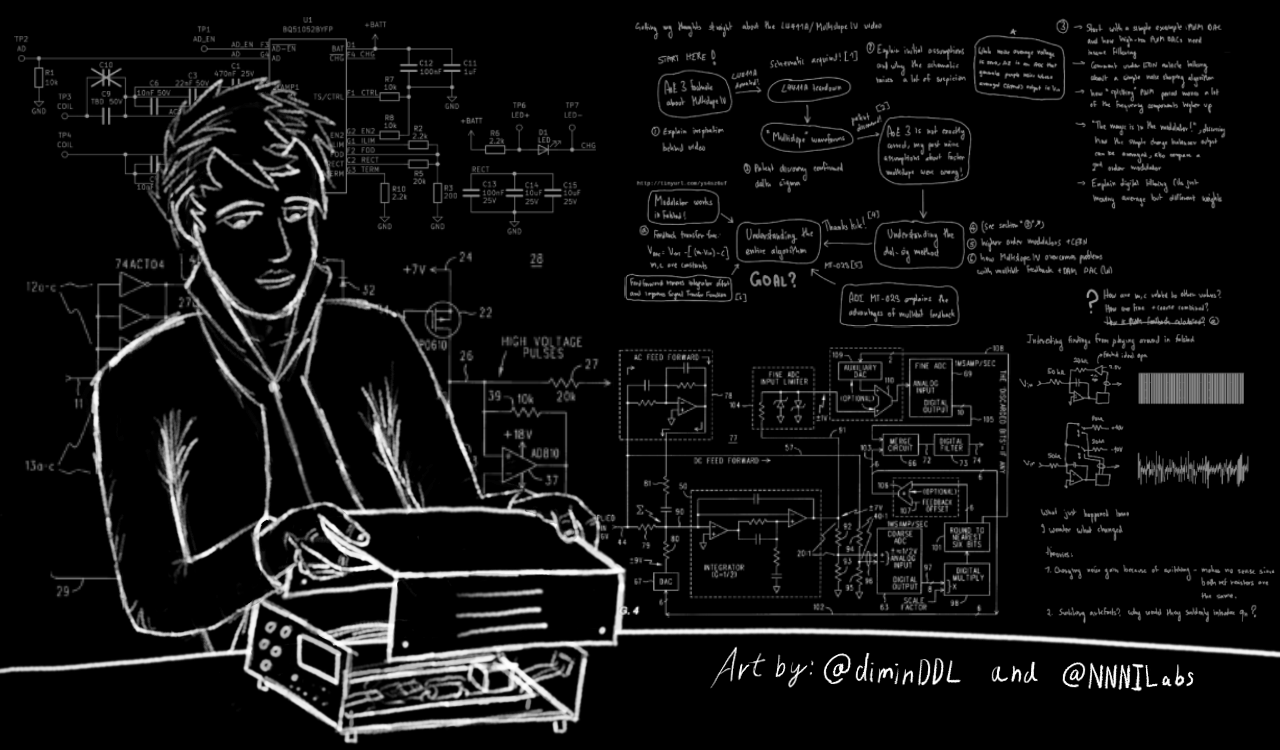

A special thanks to all the people that helped me with everything:

@NNNILabs,

@Cuprum,

@UtsuhoDoesScience,

@XilinxDerg, and many others who saved me in other ways,

or wished to remain anonymous.

What is "Electronics"?

Over time, electronics has expanded into numerous specialized areas. While it's possible to make some broad generalizations, the most effective outcomes often result from a multidisciplinary approach. Almost every conceivable project involves a blend of various fields, including analog, power electronics, microcontrollers, computer architecture, and RF, to name a few. Indeed, each of these areas is a world unto itself, waiting to be discovered. Additionally, proficiency in working with hardware on a more comprehensive scale, such as with computers, 3D printers, and acquiring skills like reverse engineering, proves to be invaluable.

Now here are the things you will be able to do with enough time and resources once you have absorbed a reasonable amount of knowledge from the above-mentioned fields:

- Design and build pretty much any electronic device imaginable.

- Perform component level repairs for pretty much any electronics.

- Bend consumer devices to your will and make them do things that the manufacturer never intended for them to do.

- Be able to reverse engineer existing products by just having a working sample.

- Be valued on the job market, since demonstrating the ability to independently construct and or write code for a commercial-grade device speaks volumes more than promises and words on paper.

- The ability to understand why devices work the way they do and understand the compromises that went into designing them. This ability is very quickly gained by working on projects. In other words, it puts you in the shoes of the designers and manufacturers of a product.

- Be able to judge the security/tracking risks of devices in our increasingly connected and surveillanced world.

- And many others…

And no, you do not need a university degree to do those things, there are high schoolers who did the above even before they were formally allowed to enroll into a real university. A formal electronics course familiarizes you with mathematical analysis of a circuit, and will sometimes let you make a few devices at no expense to you through course projects. But you would likely require more experience to get good at it. A formal education certainly helps (if you actually studied) and also provides a good opportunity to network with people with similar interests. But it is by no means a requirement, it was not for many people, so don't despair if you don't have a degree yet or already have a different one.

You read the preamble and are now actually interested and want to start learning, what now?

First of all you need to be warned. This journey will likely take years and will require material investment, it will be gradual but still when you add up all the sunken costs half a decade later you might get a bit upset. Also, for the first few months if not years you will be failing, constantly failing. I learned this the hard way, nothing I built worked and I was just left wondering why. If you get discouraged by this, then maybe you should consider a different hobby, because failure is the name of the game. No one can design a piece of electronics that works perfectly the first time, you will need several revisions at the very least to get things right, even when you are experienced. Electronics in my opinion is the inverted version of the 80/20% rule (Pareto principle). Here you will first spend 80% of your effort and time to learn 20% of the information and after that you will start learning the more complex stuff a lot faster. Another piece of advice is to keep an open mind and reach out to others. Find a forum, a discord server, a friend, anyone you can talk to in case you have some trouble. Do not bother people excessively and respect their time and the free help they are giving you. And before asking, try searching if someone had a similar issue before. Knowing the right place to look for solutions is an important skill that carries over fluidly to all aspects of life. You are never left wondering "what should I do next?". Instead, you already have a concrete plan to test, debug, replace, etc. When you do need to ask a question you should include as much relevant information as possible, what you tried, what the effects were, and the likes. You can read this for a pretty good summary on what makes a good and answerable question.

And finally, I need to mention, there exist sections of electronics that can very much kill or injure you. These include high voltages/currents, high RF, light, thermal or chemical exposure among other things. If you are unsure about something, ask someone more experienced, read about the potential dangers from MULTIPLE reputable sources such as papers, occupational health and safety standards etc. And no, your health and safety is more valuable than even a cool project. But do not let this scare you away. Many hobbies include hidden dangers like this that are often dismissed, for example doing wood or metal work can easily do a lot of damage if those activities do not scare you, then electronics should not either, here the dangers are just a lot more hidden and less apparent than in other places. For instance, woodworking can pose risks such as cuts from saws, injury from kickback, dust inhalation, and noise-induced hearing loss. Metalworking involves hazards like burns from welding or cutting, exposure to hazardous fumes, and physical injury from heavy materials. Gardening can expose one to toxic plants, insect bites, and musculoskeletal injuries from repetitive tasks. Even seemingly benign activities like painting can involve exposure to volatile organic compounds (VOCs) in paint fumes, which can have long-term health effects. As you can see, there are dangers everywhere, and being aware of them is what's important.

With all of that said, If you stay within low voltage and or digital circuits, you should be relatively safe. But please take the time to educate yourself and know how to stay safe.

You have read the above and agreed to the license agreement and understand what might expect you, time to get

started!

Most of us do not learn something simply because we want to. Unfortunately most people do not have the drive to just

keep reading a dry technical document, or solve equations to calculate the correct resistor in a circuit without a

higher purpose. So, let us get such a purpose, think of something, absolutely anything electronic, a device that would

either be useful to you, or even just cool to look at, as long as it is within the realm of possibility, you can

probably make it. If you need some inspiration you can just look at hackaday or youtube and find something that you

would like to have. It is okay even if the device already exists and can be bought, making your own is way more fun

anyways. For example, the thing that started my journey was trying to make a fan speed controller for my PC. After

that I did some other things that would be "nice to have '' or just "cool", these included: soft start circuit for

lights inside a car, motor speed controllers, a 3D printer, wireless sensors and switches, and a POV display among

other things. Most of them either didn't work at all, or didn't work very well, but the longer I worked on this whole

thing the better the projects became over time. Finally in my 20s (I started when I was 13-ish) did I reach the zen in

which I can actually probably just design about anything. But the problem now became having enough free time with

all

the adult things that I have to deal with 🙄

Below are some stories from the contributors to this article:

I started tis journey first trying to make a hoverboard in 2014, then an electrolaser in 2016, which morphed into a microwave gun, a laser gun, a coilgun and eventually a railgun. Six years down the drain, and then suddenly I got interested in analog design and has been hooked since.

Ever since I was small I have been interested in how various things work. At first I was interested in popular science media, but it couldn't satisfy my curiosity. My parents got me a few toy electronics learning sets, but those became boring rather quickly. That is when I decided to use some unconventional parts like the microwave oven transformer (MOT) that I got from dissembling an old microwave. I was scared of mains back then so that surely saved my life, but I will never forget the shock that I got from playing with a small battery and a MOT... Only after a decade, which included few years worth of learning theory and trying to connect it with practice I understood that I had made a very crude boost converter... In the end with multiple projects behind me I have to say that it was worth to learn electronics on my own.

Now that you have selected a project, let us start from the most important part. Research! Chances are that someone did something either very similar or nearly identical already. So, you hop onto your favorite search engine and search the right keywords to look for what you want to make. If you found something - great, you can just copy that design and along the way look at what all of the different parts mean. Using the fan speed controller as an example, let's say I found a forum post where someone was explaining how they made theirs. I see some photos and a sheet with symbols. This is what is known as a schematic diagram, these are the bread and butter of an engineer, not only in the electronics field. Diagrams are useful for abstracting away either the physical details of the implementation (for example how we will actually solder the circuit together) or they abstract the implementation detail and just focus on the larger picture (also known as a block diagram, where we just have blocks of subsystems that need to interact). Regardless of which type of diagram you are looking at you will need to learn to "read" them. There are many places that explain it pretty well, and just searching for "how to read a schematic diagram" will get you there. Here you will learn that the schematics actually represent physical components. And with the simple search terms of "what is a resistor/capacitor/transistor…" you can once again find plenty of resources explaining those. As you can see search engines and the internet will be your best friend throughout your journey, so learn to use them. If you come across an unknown term or concept, just look it up and you will likely find some pretty good explanations. In case the thing you want to make doesn't seem to exist then it's time to either choose something simpler. Or break your project down into smaller pieces and start from there. Sparkfun has a pretty nice collection of introductions to the specifics if you need that.

So, you have found a schematic that appears to suit your needs. Or if you didn't here are a few things you can try to get the basics:

- NE555 LED blinker

- Multivibrator circuit

- Temperature controller

- Lab bench power supply

- Fan speed controller

Now you can take two paths, you either start simulating it and verifying that it does indeed work as expected on the computer first, or you go straight into building it and seeing what happens. During my journey I often did the latter, and regret it now. Learning electrical simulation is a bit daunting, but 100% worth it. It saves a lot of time and head scratching if you can just build blocks of your design and test them virtually. I at first used the free version of Proteus to simulate stuff since it has a very interactive GUI. But it did not allow saving files due to the free version, so after that I moved onto Falstad for quick and dirty prototypes and LTSpice for serious evaluation. The difference between all the simulators out there is usually the degree to which they simulate the parts in your circuit. For example Falstad makes a lot of assumptions to simplify the math and allow it to run in your browser, for many cases such as just prototyping something to see if it would work this is fine. But for more complex designs where the exact details matter it is better to use something like LTSpice which simulates a lot of the real world imperfections better approximating what is going to actually happen after you assemble the circuit, this is thanks to the more accurate models for REAL transistors, op-amps and other components. Falstad is the easiest to use, so I would recommend you start there. LTSpice, QSPICE, Proteus and many similar "big boy" simulators are a lot less intuitive and the user interface can be a bit outdated. But the laws of physics did not change and the internet is still there to look up tutorials and documentation, so do not hesitate to use it whenever stuck.

When the simulations are done you presumably want to save your schematic, keeping it in the simulator file format is fine, but using a proper schematic capture software is nicer since you get stuff like fields for part numbers, values and convenient ways of interacting with it for later endeavors such as converting to a PCB. So, I recommend you draw your schematic in KiCad. However, the skill of keeping your work organized will be invaluable here. Being able to create a *readable* schematics will save you and anyone you share the schematic with a lot of time trying to decipher it. Trust me it's better to start doing things properly from the start then to later try and fix them. A resource I would highly recommend taking a look at is Appendix B, The Art of Electronics, 3rd Edition book. (More info about resources at the end of this page)

Just Like The Simulations

After simulating or otherwise evaluating your circuit comes the most dreaded exciting stage - assembly. Now

this is

the first place where you will need to invest some money. I recommend investing in a good quality (for example the

BB830) breadboard and some jumper cables for it. This will let you quickly check circuits without having to solder

anything together. You can find some good info on the quality of breadboards here.

When you decide to solder your circuits together you will need a few things, first of all a soldering iron, thankfully we live in a day and age where very good models such as the TS-100 or the PINECIL have gotten quite affordable. If you however want something even cheaper, go for an iron with a ceramic heater (usually looks like a white ceramic rod under the tip) and some sort of power/temperature control, it will be good enough for doing through hole assembly. Next come the supplies to start soldering, I recommend you go straight for good lead free solder since there is no reason not to if you have a decent iron. Sn96,5 Ag3 Cu0,5 flux core is what you are looking for, I use this solder daily, it melts very well at 350C and produces quite nice joints. Leaded 60/40 is a more common option as well, but I would avoid it if you can, and if you need to work with it, take all the necessary precautions for working with lead. While leaded is easier to use, the reality is that the world is moving away from lead, and it will get harder and harder to find it over time. However, you also need another component to achieve good soldering, flux. Flux removes the oxides from the surfaces you are soldering, resulting in a much cleaner and better joint, once again you should look more into it using your favorite search engine. I use AMTECH NC-559 and never had any issues with it, some people also recommend MG Chemicals - 8341. You are of course free to deviate from this and use whatever you like, this is just what I found is the most available and works best for me. Finally in order to mount all the components and make connections you'll need some proto boards and wires.

Howeverver, what do you do if this is all a bit overwhelming and you don't know if you want to invest into all the equipment and supplies just yet. Good news, there are plenty of places that likely have all of the above and would probably let you use it for free or a small fee. Tese spaces include school workshops, university labs, hackerspaces and sometimes even places like libraries or IT helpdesks. Don't hesitate to ask your local institutions, explain that you are trying to learn, and they will likely be happy to help you.

But where do you get the components? Once again, we live in a day and age where you can just order them from a local reseller and they'll be shipped to you within days. If you are in a place where the local shops are not that great, or they don't have what you need, then you can refer to the following list comparing some (not all) international component suppliers:

- Reliable and largest selection of parts - Digikey, Mouser, Newark, Farnell. (These often have significantly higher prices on lower quantities, but in return provide free shipping and handle taxes in a large number of countries. This makes them more convenient and easier to deal with than Chinese sellers, especially in Europe.)

- Pretty reliable, cheaper for some stuff like passives/simple stuff, smaller selection - TME, Arrow.

- Reliable but reports exist of fake parts, extremely cheap for some stuff, super expensive for other - LCSC

- Lottery... Can have hidden gems such as displays from some dead smartwatch company or a stack of salvaged boards from somewhere, but you need to be realistic, if it seems too good to be true, it probably is - Aliexpress, Alibaba and similar.

- Local suppliers can be a good choice too if you can get parts in a walk in store at short notice. However, their selection is usually quite limited and requires you to get a bit more creative.

If on the other hand you didn't decide on a circuit yourself and want to build something simple and random, you can try electronics kits. They usually have everything you need and probably will just work. Although they slightly diminish the learning potential because of that. But it can be a good way to practice soldering…

You can also pull components from old electronics, such as old computers, power supplies and the likes. But this activity involves some risk regarding possibly dangerous voltages inside if the device was recently in use. There are safe ways of handling them, and the same advice as in the safety preamble apply. Salvaged components can be a mixed bag, on the one hand you are getting them for free if the device is already broken, on the other you are getting components in an unknown state. There exist quite cheap component testers that can test all the basic electronic components and give you a rough idea of what they are and if they work. But they are useless for quantifying anything more complex than a transistor. And the cost associated with spending your time and your consumables on salvaging make it a pretty bad deal nowadays depending on your circumstances. Usually I just survey the boards for useful things that are likely fine and are expensive to buy new. Like ADCs, DACs, MCUs, PMICs, good op-amps and so on. It's ultimately up to you to decide if it's worth your time or not.

Now comes the issue of powering the circuit. In simulations you can have any arbitrary voltage ready, but in reality it's not quite so simple. And this challenge in itself can act as a nice starter project, more on this later. There is a set of standard voltages that you can easily obtain and are most likely to actually need, the rest usually requires some custom setup, like a DC-DC converter or a purpose built supply.

Below is a list of standard voltages you should aim to use and where to easily obtain them:

- 0.8V - 1.8V: these voltage rails are quite rare because they are usually used inside chips powering stuff like the logic itself. If they are not generated inside the chips, then specialized LDOs or DC-DC converters are used to supply them. You will rarely come across them in the hobby (unless you go hard into SoCs and FPGAs), but it's always good to be prepared to face them, some I/O interfaces on devices like ADCs and DACs have 1.8V levels. Level shifters can be useful to connect them to something like a 3.3 or 5V microcontroller - two resistors per pin can also do the trick sometimes! (try figuring this one out!)

- 3.3V: Most modern microcontrollers and digital electronics, including battery-powered devices, operate from 3.3V supplies. Bonus - the Raspberry Pi Pico, the authors' favorite microcontroller board, has 3.3V supply rails.

- 5V: The bread and butter of modern electronics; can be sourced from USB ports or power banks for low-current applications, and from ATX PSUs or dedicated supplies for higher current capacity. It is worth mentioning that 5V USB is not very clean or stable, it's fine for digital application, and maybe some basic analog with filtering, but it quickly becomes way too much effort to use.

- 9V: Also pretty standard; can be obtained from 9V batteries or quite common wall adapters.

- 12V: One of the most common power supply voltages in consumer electronics. ATX PSUs have very powerful rails for this one; AC adapters are very often 12V as well. This is also the voltage found in many lead acid batteries meant for cars. But because of that they have a looser voltage tolerance (anywhere from 11 - 14V is possible with even higher short spikes if you are sourcing it from a running car's battery). So, unless you derive this voltage from something like an ATX PSU power rail, be aware of this.

- 15V, 18V, 19V, 21V, 24V, 36V, 48V: Some common higher voltages.

It's nice to have your circuit operate on a standard power supply rail, but sometimes you might want to test some things or adjust the voltages in real time while your circuit is working. This is where another beginner project comes in. Building a lab bench power supply. This device will allow you to set any arbitrary voltage within some boundary (depending on the design) and maybe even current limit the supply to reduce the chance of your circuit blowing up if you made a mistake. You can make one with minimal components and very good performance using an LM317 and a wall adapter to supply it. But once you outgrow that one and will start looking into either buying or building a more complex one, then it's worth keeping in mind that for most applications a range between 1-30V and 0-3A will be sufficient, and it's better to have a few isolated channels than to have one more powerful channel. There exist quite good PSUs that can be bought from reputable distributors and even amazon under the brand of "Korad" at affordable prices. Also, beware of the bottom of the barrel PSUs, they can come with high noise and protections that don't work correctly, so consult honest reviews before pulling the trigger.

Once the circuit is assembled and powered, it may not always be immediately apparent whether it is functioning properly, especially if it lacks visual indicators such as LEDs or a spinning motor. If it's not working correctly, we need to diagnose it. Unlike other engineering fields, electronics kinda behaves like a black box. We have no way of seeing what is happening inside the circuit, so we need to use other electronics to peek inside and take a look. This is where we need measuring equipment. There are many different ways of measuring different things, but we will focus on the absolute basics here. Once again I will not go into detail on how to use them, the internet will help you with that.

The best return on investment for an electronics hobbyist is a DMM (Digital Multimeter). This small box lets you measure a wide range of voltages, currents, resistances, capacitances, temperatures and even more depending on the specific model. You can get started with a cheap basic model, but you will likely quickly outgrow it and would want something better. However, be wary of the cheaper devices lacking many safety features found on the more expensive DMMs, so please exercise caution and treat any equipment connected to dangerous voltages as potential hazards. (Shitty DMMs can ✨ explode in your hand ✨ electrocuting you on the way if you shove them into high energy places like mains, big batteries, large inductive loads and others). Here it's better to invest in something more expensive upfront if you can. In the last few years prices for decent DMMs have been coming down and they became quite affordable.

However, if your circuit does something over time, like generate a PWM signal, or amplifies a signal, then you can't measure them with a DMM. This is because DMMs (and your eyes) can only meaningfully process a few 10s of updates per second, to really see what is happening in a fast circuit you need several orders of magnitude more samples every second. This is where an oscilloscope comes in. All it does is it lets you plot voltage over time. While that might seem simple and trivial at first, doing it quickly (several thousands to billions of samples per second) and being able to perform measurements on the results is the best part about it. An oscilloscope lets you instantly cross correlate your results with your simulations and probing around different points lets you know where the problem is coming from. An arduino or a pi pico can be used as a makeshift oscilloscope for some simple stuff, but it can't replace the real deal.

This is probably the most expensive (for most people, unless you decide to do RF, metrology or something else silly) piece of equipment you would want to buy. You can start without one, but getting it is like being able to see after being blind for a while, and it definitely allows you to spend less time guessing and more time actually fixing the problems. So, if you can, I strongly urge you to get a Digital Storage Oscilloscope (DSO) as soon as possible. The cheap Chinese handheld stuff might seem appealing, but from experience it's absolute trash. You want something with at least 1 GS/s, 100MHz and 2 channels (4 channels is A LOT better than two tho, if you can - definitely splurge for that). The higher the sample rate and bandwidth the better, but another thing to keep in mind is sample depth, this is how many points the scope can keep in its memory for you to look at. Older used models might have great sample rates and bandwidths, but terrible memory depth, so beware of that. Also sampling (and analog) oscilloscopes can be a trap if you want to look at quick non repeating waveforms, it's better to avoid those unless you know what you are doing.

As alluded to above, you can go for used equipment if you want to save some money, here are some brands that are trustworthy and should give you exactly what they claim:

Premium category:

Tektronix, Keysight (Agilent), HP, LeCroy, Rohde & Schwarz - These brands have been around for decades and are well-respected in the industry for their quality, reliability, and good feature sets. They tend to be preferred by professionals and institutions that require high precision, durability, and serviceability. All that comes for a price - an extremely steep price. Keysight's 1000 X Series are the cheapest of the bunch, and start at around 450 Euro. And many of the features are locked behind a software paywall (you thought unlocking heated seats in modern cars was bad, oh boy will this infuriate you).

Cheap and good category:

Rigol, Siglent - These brands are for hobbyists, and those with tighter budgets. They offer a good balance between performance and cost. And usually don't blatantly lie about their specs unlike the next category.

Cheap and questionable category:

OWON, Hantek, FNIRSI, Suin and the likes - while these brands provide decent value for money, they may come with

compromises in performance, build quality, software and reliability. Unless you absolutely have to, I would advise

against these. If you have no other choice then make sure to carefully research forums and videos online to make sure

you are aware of the limitations. Or better off, just avoid them and save yourself time, money and trouble. Here is

some more info to drive the point home:

Hackaday article,

EEVblog video

And to make your search easier, here are some things that are and are not so essential in an oscilloscope:

Stuff you should have:

- Advanced triggering is very useful for diagnosing intermittent behavior. Pulse length range triggering, dropout detection and protocol triggers (I2C, SPI, etc.) are some examples of advanced triggers I use quite often.

- A large high quality display with a good UI makes it easier to stare at the thing for hours.

- External control and readout options, USB, Ethernet, Wi-Fi, web server and such are super useful for reading and controlling it from a computer for more advanced data logging and analysis, or just showing what your circuit is doing to others/documenting your work.

- Digital phosphor is also a very nice feature that lets you see not only the instantaneous signal but also the general "trend".

- FFT and other math options are a great tool for evaluating stuff like noise, harmonics and distortions.

Nice to have:

- A signal generator, bonus points if it can do bode plots.

- XY mode, can sometimes be very useful, but rarely.

- Extra channels, 2 channels is the absolute minimum, but the moment you want to step outside the simplest of circuits then 4 becomes the obvious choice (many modern motors are 3 phase BLDCs, sometimes you want to probe something like 3 wire SPI and a DAC output, etc.) so, you should go for the 4 channel if you can.

Stuff that is nice to have, but may not be worth to spend extra on:

- Digital channels, it's usually better to get an external logic analyzer and use it on a computer than deal with the limited built in tools of the scope.

- A touchscreen, generally speaking, it's not that convenient and I found myself just using the hard buttons and knobs.

- Storage inside the oscilloscope itself. Some scopes offer the option to store waveforms and whatnot inside the scopes memory. The utility of this is debatable.

Also, before starting to use a scope, please read all the relevant instructions and warnings. Learn about the isolation, where ground is connected and what happens when you connect it to a computer and use the ground clip on a high potential relative to mains earth. EEVBlog has good videos on the topic. The Siglent manual also does a good job describing most of the aspects of using a scope.

In conclusion, do not compromise on getting a good DMM, Oscilloscope and other equipment. Expensive as they might be, they represent an investment and personal commitment to the hobby, and good ones will last at least a decade, ideally by which time you are ready for a more expensive upgrade. Also this sort of equipment (unlike consumer products) maintains its resale value quite well as a nice bonus.

You did it, now what?

You assembled your circuit, used all of the above to verify it and it either did or didn't work. If it didn't work - that is even better, because now you get to learn how and why it actually works outside numerical simulations and with all the imperfections of the real world, go around each point and check the signals. In the end it might start working if you find and fix some issues, or it may not. Both of these outcomes are fine and both of them taught you different things.

Regardless of the outcome you can do a few things.

- Try to improve or design a better version of whatever you made. Since nothing is perfect, you surely found some areas to improve while building and testing the thing. And now it's time to try and learn how to do so.

- Dive deeper in some specific topic. If during your journey you found something interesting you'd like to explore. For example understanding how op-amps work and selecting one from a vast ocean to fit your design, some specific trick that you thought was neat, or anything else that scratched some itch in you. You should explore that, since if you have motivation out of curiosity, it will go a lot smoother than you might expect.

- Make a new project! Maybe you got bored of this one, or it wasn't that interesting to begin with. Simply find something else to work on and repeat the same process and eventually something will work out for you. Sometimes, lessons learned from one project can be applied directly to another, so it's always nice to have a few projects to work on at the same time. You can switch between projects if one bores you or you've hit a wall.

So, this is it, the end of the general outline and tips for getting into electronics. Your main takeaway should be that: as with many skills, the real experience comes from doing something over and over again, and with increasing difficulty. With each iteration you learn a bit more, you build intuition and become better and better. Don't be afraid to fail, and go at your own pace, it's not a race and while you can aspire to be like others, don't let someone who has a different brain, different opportunities and different circumstances affect your self esteem.

Below you will find some things that didn't really fit in the overall vision I had for this article, so instead they are here as a resource in case you want more detail from some experience in each field.

Appendix A: Computers, Programming and Embedded by dimin

After dabbling in analog circuits for a while I discovered the existence of Arduino. I always was a bit into programming, and the ability to control my circuits with code blew my mind. Arduino is a very nice starter platform, it just works, you don't need to think about the complicated backend and you have foolproof functions to help you out. However, it requires you to start learning a completely new field of low level programming, protocols, computer science concepts and such. Writing software can be a hobby all on its own, but the blend of electronics and programming is an incredibly powerful combination. For example, while you can use counters, shift registers and logic gates to add some “smarts” to your electrical circuits, it's usually a lot cheaper and more convenient to add a microcontroller and simply write some code to describe what you want it to do.

The field of Digital Signal Processing on the other hand blurs the lines between digital, analog and mathematics - it lets you read in analog signals, modify them in various ways with code and then output them back wherever they need to go for example. Such techniques can allow for some behavior which would be unreasonably difficult or impossible to achieve purely in analog. (For example, noise shaping, advanced signal synthesis and crazy filters.)

Knowing digital electronics also allows you to mess with most modern appliances and devices more. For example you can write custom firmware for your internet connected kettle, or hack the EEPROM on your toothbrush to add custom profiles and much more!

Ultimately you only have so many hours to invest into different skills, so it's up to you to decide if you want to mess with computers or not.

Below is the order I learned things in, feel free to pick out the interesting ones to you (if you don't know what they mean, you should already know what to do):

- Basic desktop C++ programming.

- Basics of analog design and electronics.

- Dabbling in Arduino.

- Learning AVR C.

- STM32 and their entire software stack.

- Espressif ESP8266 and ESP32 through PlatformIO.

- Python scripting.

- RP2040 and the PicoSDK ← my current favorite due to an excellent SDK with low overhead, good documentation and no bloat!

- High Performance Computing and GPU programming.

- FPGA programming with VHDL.

- Fundamentals of Superscalar Processors.

- SoCs and how to build an OS for them.

- ...

Appendix B: Analog will outlive those who claim it's already dead! By NNNI

advanced maths eventually becomes relevant and necessary for as analog magic come into play

An out-of-context quote from an online chat platform is perhaps not the best way to introduce (or justify!) the title of this section, but it does make an important point.

Surprisingly enough, both analog and digital computing were born and grew up together - even as electronic analog computers were being used to calculate ballistic trajectory for projectiles in World War II, Claude Shannon was busy at work writing his seminal papers on relay logic and information theory.

As Apollo was taking humans to the Moon with the help of a digital computer that consisted purely of RTL ICs with not more than a couple of gates per package (3 input NORs!), Bob Widlar was creating the first IC op-amps (among other things like linear regulators) at Fairchild Semiconductor.

For the most part of the early years, the limiting factor for the growth and complexity of digital circuits was the fabrication process. Large transistors, only a few of which could fit in a given die area, were perfectly adequate for simple analog functions, but greatly limited what digital circuits could be made. Basic gates were possible, but a large number of such ICs would be needed to make a practical computer. As semiconductor processes matured and made smaller and smaller transistors possible, the digital domain was quick to take advantage of the explosion in transistor density. Analog circuits, however, cannot really take advantage of transistor density the same way digital circuits do. Noise, leakage and a lot of other factors complicate analog design with very small transistors.

It was at this point, around the 1970s and 1980s, that the large schism between analog and digital emerged. Increasingly transistor-dense (and function-dense) integrated circuits made general purpose computers for home use possible, and everyone had access to some kind of computing device. The Internet made it possible to connect computers all over the world, and computer science (although it was already a very well established field by this point in time, with all the groundwork already done) exploded.

In the year 2025, computers are everywhere and continue expanding into every facet of life, showing no signs of slowing down. The computing power available to electronics hobbyists is incredible. The Arduino project from the early 2000s put microcontrollers in the hands of hobbyists with an easy-to-use software framework.

The appeal of digital control is easy to understand. Dealing with individual transistors or gates is no longer necessary. Instead, everything is neatly abstracted and the only thing presented to the user is a monitor and a keyboard. And, of course, the requisite software. With a few keystrokes, you can make an LED blink, drive an LCD display, or even perform advanced signal processing like image recognition on a 20 Euro microcontroller. Things just work - and if they don't, it is easy to take advantage of the fact that computers are completely deterministic. They follow every instruction you give them down to the last T. 'Garbage in, garbage out' is a popular phrase that sums up working with computers and digital electronics. If something goes wrong, it is easy to determine the cause based on the expected output for a given known input.

However, analog circuitry usually does not afford the user this luxury. Even the purest sine wave, when fed to an analog circuit, might produce an unexpected distortion. The input-output characteristics of the circuit no longer purely depend on the circuit and component values themselves, but also shows a high sensitivity to how it is constructed and powered. There is some margin that one can 'get away' with, but after a certain point, careful attention has to be paid and knowledge of what one is doing is necessary. This knowledge and experience is not easily earned and needs multiple years of blood, sweat and tears to gain. Once you have made enough mistakes, you are more careful when constructing your next analog circuit and take into account all previous mistakes and take steps to avoid them.

This notion of 'determinism' (or lack thereof) brings me back to the quote that started this section. In 2024, the pain and frustration that results from trying to make even a simple amplifier work has put up an invisible barrier around analog as being 'difficult'. Knowledge of advanced mathematics has been successfully used as a gatekeeping tool in many places, and it is no different here. “Greybeardism” and “magicism” (the tendency to think that only 'greybeards' are capable of doing something, or just attributing something complex to magic without trying to understand it) are only detrimental to getting more people interested and engaged in building analog circuits.

The truth is, Bob Widlar's original patents and app notes are devoid of any advanced mathematics. You can go surprisingly far with just the basics and a few rules of thumb, since the circuits themselves are performing the math for you! Circuit simulators like LTspice also help greatly, and intuitive analysis techniques like the Bode plot eliminate the necessity for advanced calculus. This is not to say that mathematics is not a useful tool - in fact, knowledge of mathematics helps greatly with complicated analyses and modeling - the point being made here is that you don't need a PhD to get started and get quite far.

The incredible pace at which digital semiconductor fabrication is progressing has sprouted claims of analog being a 'dead' field. This is equivalent to saying that your company does not need an IT security team because you have never been hacked before. As much as the digital prophets might like to think, the world we live in is not discrete (proponents of quantum theory might tend to disagree, both with this and the determinism statement above) but consists of values that vary continuously. This data has to be extracted from the real world in order to be processed by the digital machinery we have built up over the last few decades.

Single digit nanometer processes are the cutting edge of digital semiconductor fabrication today, while the most advanced analog ICs (chopper op-amps and mixed signal circuits like ADCs and DACs) are still at the double or triple digit micrometers.

With that being said, great efforts are being made to adapt analog circuit construction techniques to digital processes. The AD4080 40Msps 20-bit ADC from Analog Devices is the latest showpiece for these results. Incredible analog performance has been achieved by using 'computery' algorithms like DEM. Workarounds involving multistage conversion also enable high resolution.

While single (US Dollar) cent microcontrollers enable reckless use of programmable devices in even the cheapest and simplest consumer product, analog ICs like op-amps will always have a place. The need for test and measurement will never go away. Even ADCs need a front end to interface with the real world, and currently, discrete analog ICs are the only way to achieve this.

Analog is not dead - while the field might not be growing as fast as computer science, it still forms the broad and strong foundation upon which all modern digital hardware relies. While it might be complex to get an analog circuit working, the process is rewarding and teaches you a lot. As more and more computer science graduates are churned out amidst cries of "AI!" and "Analog is dead!", those who engage in the art and science of analog circuit design continue working quietly, knowing that in an ever-digital world, their skills will be valued more and more.

Appendix C: Resources

The Bible of electronics - The Art of Electronics, 3rd Edition by Paul Horowitz

A lot of good introduction material - All About Circuits

A book designed to encourage scientists to learn and apply electronics, covering many aspects and applications of electronic circuits in science - Electronics and instrumentation for scientists by Malmstadt, Howard V.